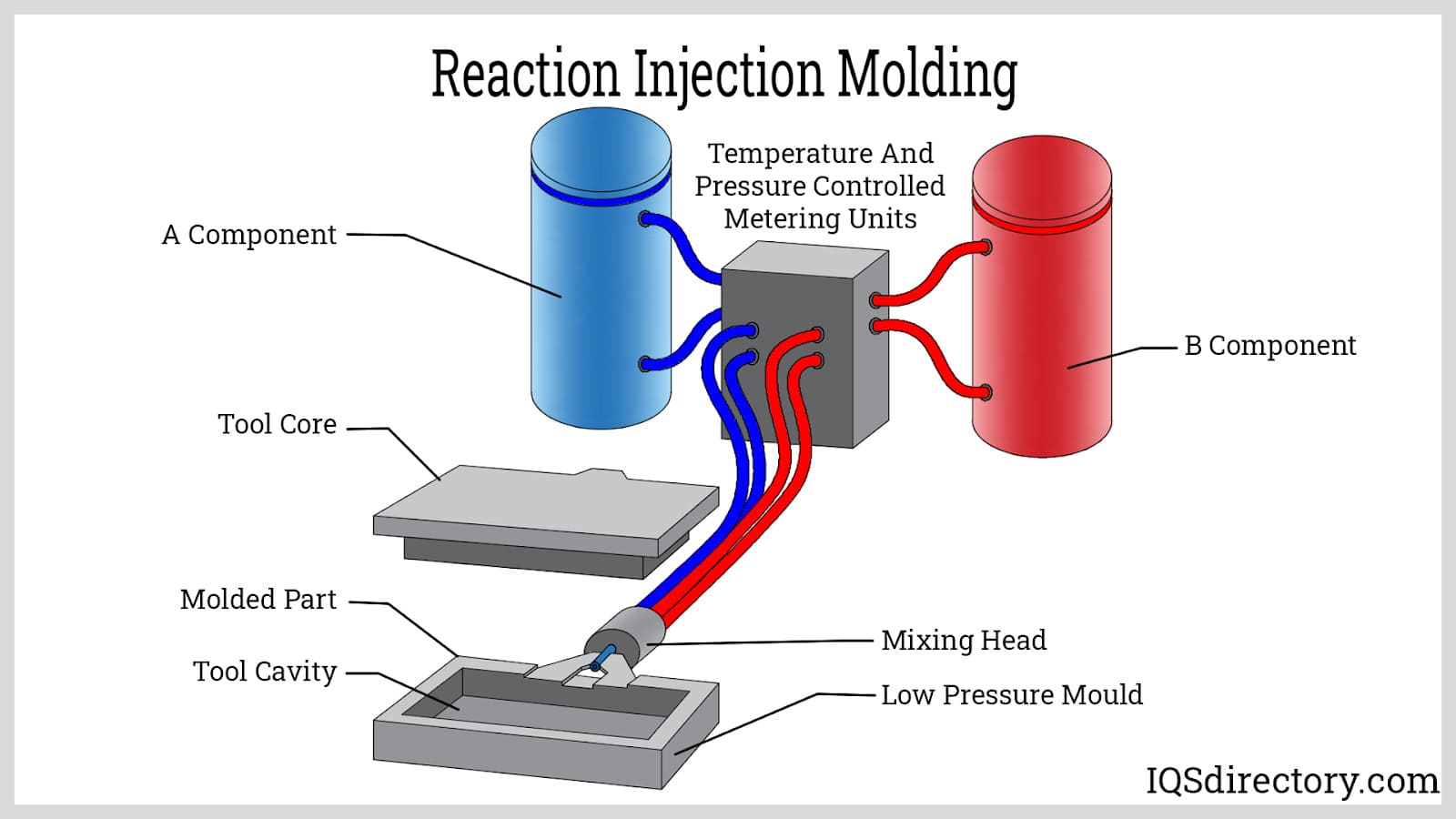

Reaction injection molding (RIM) is a polymer part manufacturing technique that involves direct polymerization in the mold via a mixing-activated reaction. Impingement is used to combine two reactive monomeric liquids, which are then injected into the mold. Read More…

For 50 years, LTM Plastics has been a leading manufacturer of injection molded plastics. When working with LTM Plastics, our customers can be assured that they are getting high quality products at a competitive price. We pride ourselves on our team’s communication and collaboration with our customers to meet their needs.

Hi-Rel Plastics & Molding, Inc. offers injection molding for a variety of industries. We can process an almost infinite variety of thermoplastic resins, our prices are competitive, our delivery is on time, and we provide superior customer service. Value-added services include label application, assembly services, and custom packaging and shipping. Our team has the knowledge and expertise to...

Quality Plastics, LLC. has become a premier leader in the injection molded plastics industry through our hard work and dedication. Out injection molding capabilities allow us to manufacture sizes from 55-1300 tons. Quality Plastics, LLC. is your trusted manufacturer for all injection molded plastics needs.

At TMF Plastic Solutions, precision and quality define our approach to injection molding. Advanced manufacturing capabilities and a deep understanding of material properties allow us to produce durable, high-performance plastic components for a variety of industries.

At Central Plastics, we’ve built our reputation on being the dependable partner that customers can count on—experienced, approachable, and always responsive. As a custom molder rooted in the heart of California, we specialize in high-quality injection molded plastics and thermoformed packaging.

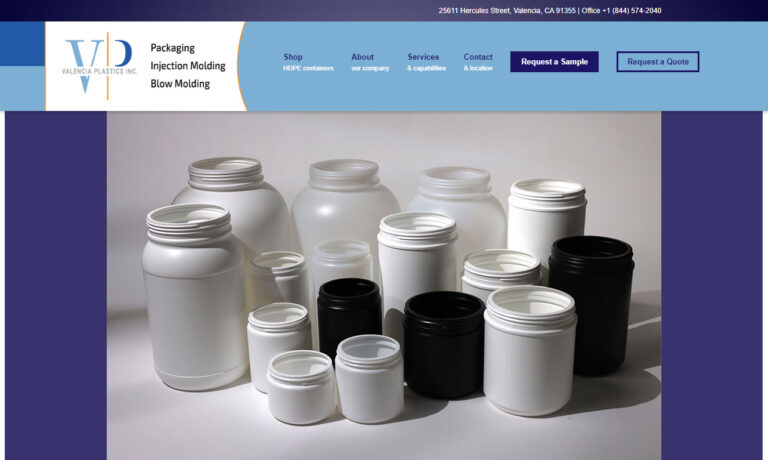

Valencia Plastics is your leading full-service injection molded plastics manufacturer. Our products are made with various materials, including urethane, polyurethane, nylon, acrylic, and polycarbonate. We offer a wide range of sizes from miniature items up to 7 lbs. large parts. We are ISO 9001:2015 compliant. Industries we serve include electrical, military, automotive, aerospace, and...

Abtec, Inc. is a manufacturer of injection molded thermoplastics for high-tech OEMs. Since 1981, we have provided quality injection molded plastics and engineering services to such industries as automotive, aerospace, dental, electronics, food handling, nuclear, reprographics and more. Our 21,000 square feet building operates 24-hours a day, 5 days a week. Contact us today!

At EXI-plast Custom Moulding Ltd., we specialize in delivering high-quality injection molding solutions tailored to our client's diverse needs. With years of experience and advanced manufacturing capabilities, we excel in producing precision-molded components for various industries. Partner with us for reliable and customized injection molding solutions.

At Zauderer Associates, Inc., we specialize in providing high-quality injection molding solutions tailored to meet the diverse requirements of our clients. Our team leverages extensive experience and advanced technology to produce precision-molded components that consistently exceed expectations.

You won’t find better quality injection molded plastics anywhere else in the industry. We have built ourselves up from a small manufacturing company to a large company with decades of experience.

At Nanoplas, Inc., we specialize in mold maintenance products for the plastic injection mold industry. With decades of experience and a commitment to innovation, we work closely with clients across industries to enhance the performance, reliability, and efficiency of injection molding operations.

More Reaction Injection Molding Companies

What is Reaction Injection Molding?

Polymerization and phase separation normally occur in the mold, after which the portion solidifies and is expelled. Automotive parts, commercial machine housings, and furnishings are among the most common applications for RIM goods.

Reaction Injection Molding Process

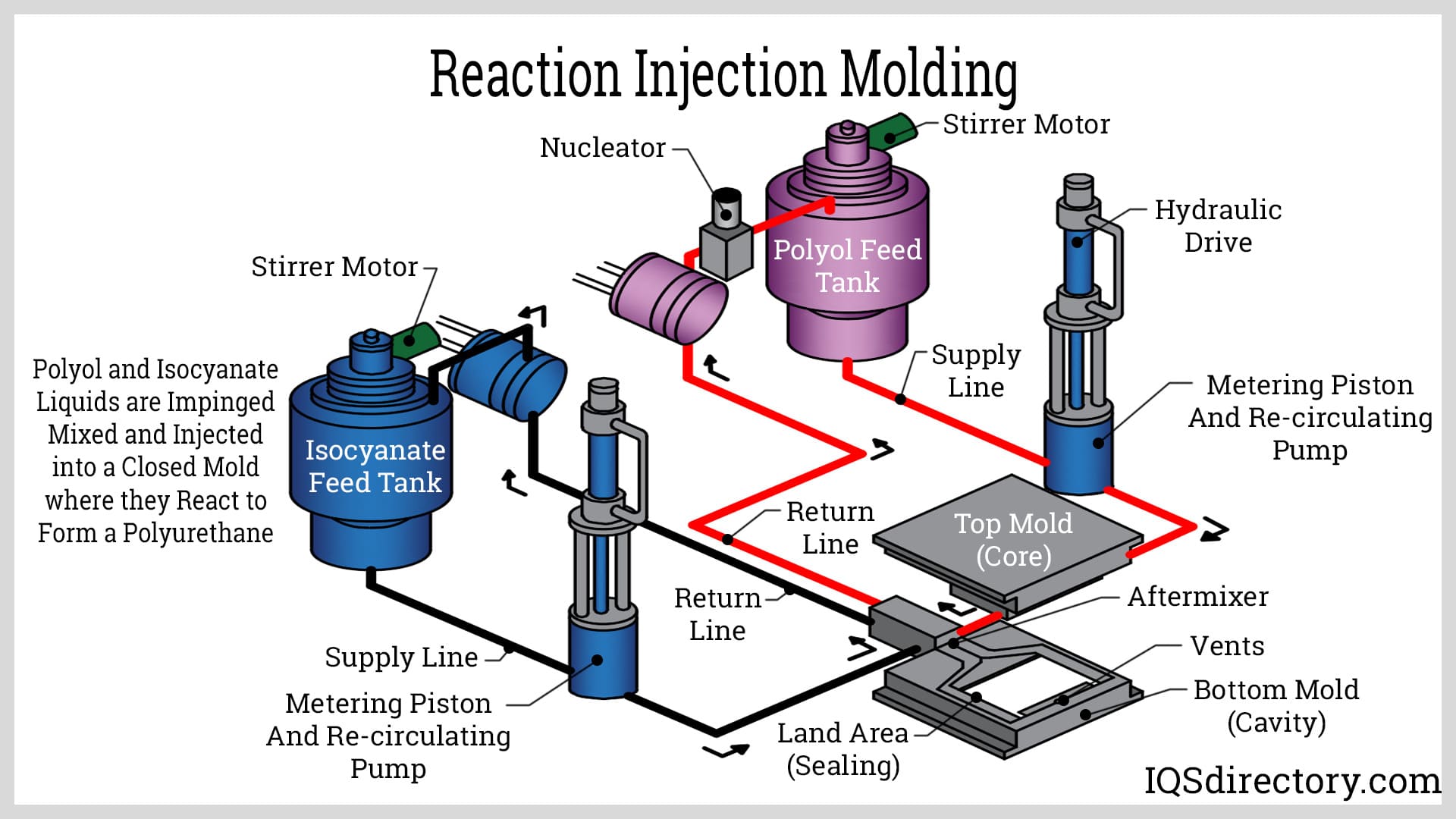

The chemical reaction that occurs within the plastic throughout the injection, curing, and cooling phases is known as reaction injection molding. At a mixhead, two liquid components – a polyol and an isocyanate component – collide and are subsequently injected (mainly by gravity) into a heated aluminum mold.

These liquids react chemically (thus the term "reaction" injection molding) before hardening into the shape of the mold cavity. As a result of the chemical reaction, a foaming activity occurs between the two components, forming a cell structure that then fills the mold cavity.

The physical qualities of the final foam material and the type of polyurethane part generated are determined by the chemistry and mix rations of the polyol and isocyanate. The foam structure may be soft and flexible, like a seat cushion, or it could be designed to react and form with little foaming action.

The reaction then produces a hard (solid), thin-walled foam that mimics the physical qualities of injection molded plastic, like a computer casing. In addition, the chemistries could be tweaked to increase impact resistance while allowing for flexibility. Another benefit of RIM is its adaptability; there is no limit to the number of goods that may be made using the process.

Because of the cure time, the size of the pieces, and the slower cycle durations involved in the process, reaction injection molds are more cost-effective and allow for greater design flexibility. Still, they have a lower production rate than normal injection molding.

Advantages of Reaction Injection Molding

These parts are tough, resilient, and resistant to aging and weathering. The reaction molding method is frequently used to manufacture molded plastic parts that must endure impact and abuse, such as radar antennae, telephone system shields, and automotive bumpers.

Due to low labor costs, little material waste, the utilization of low-cost aluminum equipment, and a variety of material alternatives, reaction injection molding is a cost-effective option for producing these parts.

RIM's other advantages over other low-volume production methods are cost reductions, part repeatability and consistency, weight savings, design freedom, and overall part quality. RIM offers high cost, weight, and quality benefits for organizations that already use FRP (fiberglass layup) as a production method.

RIM will always create a better fit and complete assembly than other methods because of the control over wall thickness and dimensional/assembly features it allows. RIM also allows large draws and varied wall sections to be created without sinking or deformation.

RIM engineers can design for both the aesthetic (side A) and functional (side B) aspects of a part and employ various DFMA principles.

Applications of Reaction Injection Molding

Due to its low processing temperatures and decreased injection pressures, RIM is well-suited for molding big components with variable wall thickness and smooth surface finishes.

Manufacturers can also take advantage of its relatively rapid turnover rate, allowing them to easily handle low- to mid-volume projects. RIM parts also have high tensile strength, are heat resistant, and are resistant to corrosive chemicals and solvents.

Long-term exposure to sunlight, on the other hand, can destroy polymer-based parts, and tooling and machining costs for polymer-based goods are quite high. RIM's steering wheels, side panels, instrument gauges, dashboard consoles, armrests, body frames, and bumpers are used by many automakers.

Some RIM components' elastomeric qualities make them ideal for use in domestic appliances, heating and cooling systems, and recreational equipment like water skis.

Parts consolidation is possible using reaction molding, which can speed up the manufacturing process and eliminate the requirement for supplementary tooling. Some manufacturers have used this advantage to create in-metal components like frames and hinges.

Reaction injection molding, on the other hand, is not suited for high-volume projects involving smaller, mass-produced components. Metal molds are costly and prone to wear throughout long production runs.

Furthermore, even minor pressure calibration mistakes in the mixing head can result in considerable variations in the amount of material injected into the mold and product cracks after curing.

Choosing the Correct Reaction Injection Molding Company

To make sure you have the most positive outcome when purchasing Reaction Injection Molding from a Reaction Injection Molding Company, it is important to compare at least 6 Companies using our Reaction Injection Molding directory. Each Reaction Injection Molding Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Reaction Injection Molding business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Reaction Injection Molding businesses with the same message.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services