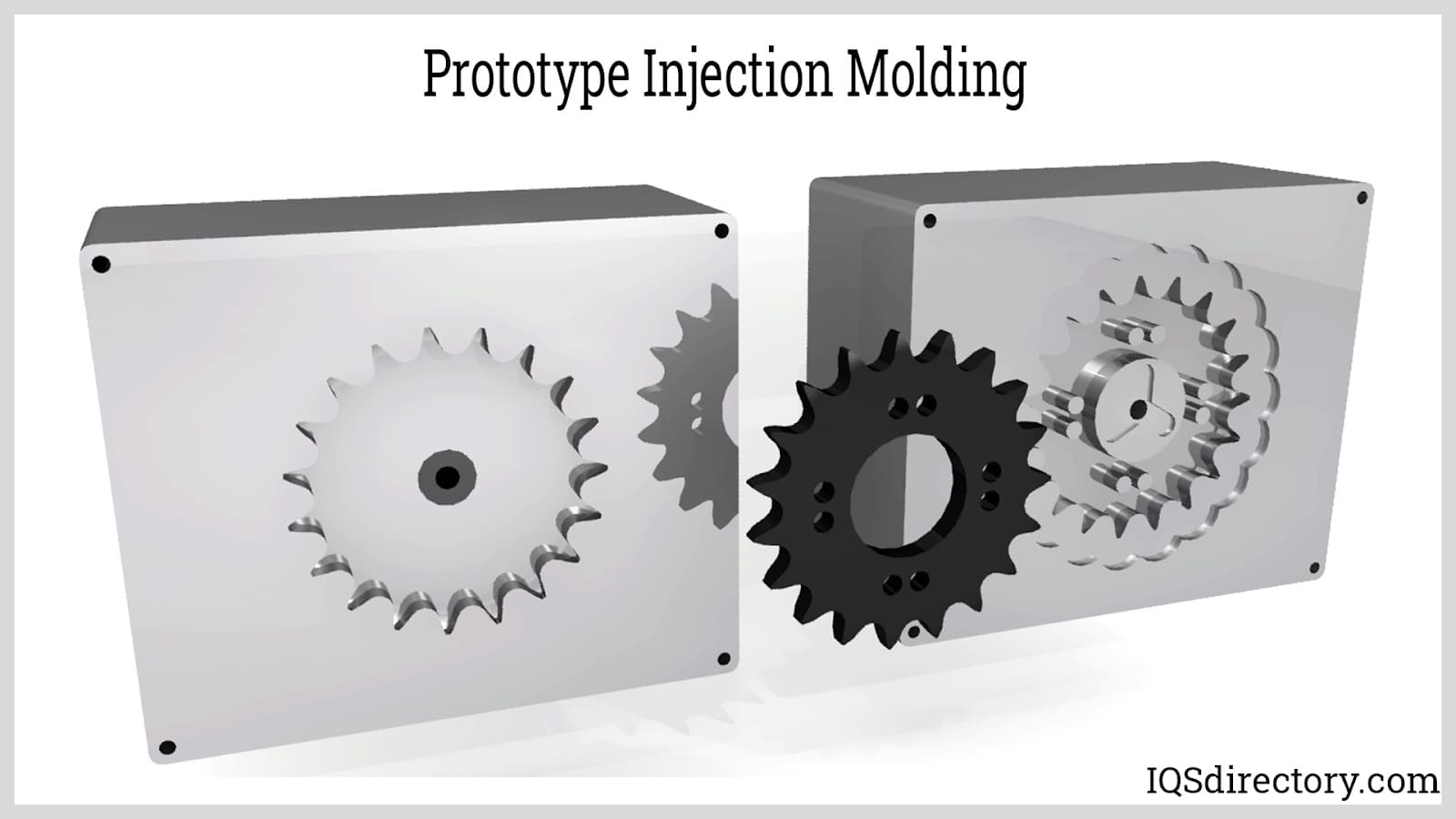

Prototype injection molding is a type of injection molding that is used to produce small quantities of products or single prototypes. These prototypes are created in the same way that long-run batches are. Read More…

For 50 years, LTM Plastics has been a leading manufacturer of injection molded plastics. When working with LTM Plastics, our customers can be assured that they are getting high quality products at a competitive price. We pride ourselves on our team’s communication and collaboration with our customers to meet their needs.

As one of the Midwest’s oldest plastic molders, Koller-Craft has craftsmanship built into its name. We take pride in our quality injection molding work. Large to small parts, short to long runs. Excelling at product design, prototyping, close tolerance molding, insert molding & secondary services.

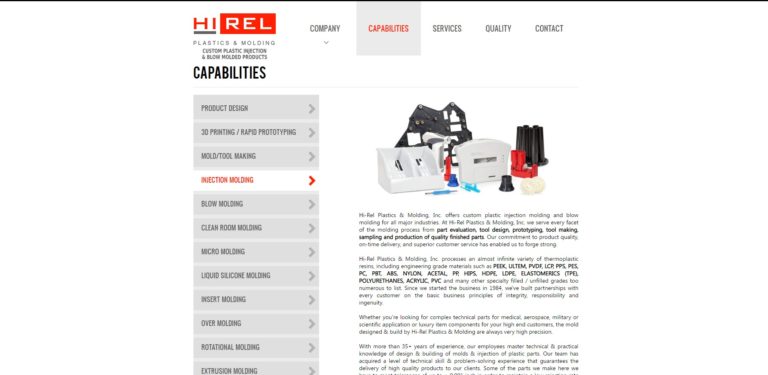

Hi-Rel Plastics & Molding, Inc. offers injection molding for a variety of industries. We can process an almost infinite variety of thermoplastic resins, our prices are competitive, our delivery is on time, and we provide superior customer service. Value-added services include label application, assembly services, and custom packaging and shipping. Our team has the knowledge and expertise to...

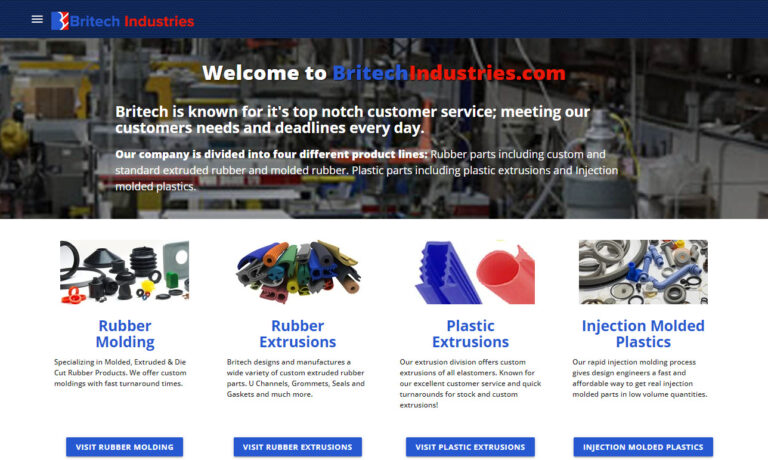

We may have started small, but today, we offer our products and services to companies around the world. We are dedicated to our customers, and our goal is to offer better service and pricing to any customer no matter the size.

Our injection molding plastics services are designed to meet a wide range of applications. We work with various thermoplastics and provide custom molding solutions that ensure exceptional accuracy, strength, and durability. From small intricate parts to larger molded components, we tailor our approach to each project’s needs.

Valencia Plastics is your leading full-service injection molded plastics manufacturer. Our products are made with various materials, including urethane, polyurethane, nylon, acrylic, and polycarbonate. We offer a wide range of sizes from miniature items up to 7 lbs. large parts. We are ISO 9001:2015 compliant. Industries we serve include electrical, military, automotive, aerospace, and...

Abtec, Inc. is a manufacturer of injection molded thermoplastics for high-tech OEMs. Since 1981, we have provided quality injection molded plastics and engineering services to such industries as automotive, aerospace, dental, electronics, food handling, nuclear, reprographics and more. Our 21,000 square feet building operates 24-hours a day, 5 days a week. Contact us today!

You won’t find better quality injection molded plastics anywhere else in the industry. We have built ourselves up from a small manufacturing company to a large company with decades of experience.

At EXI-plast Custom Moulding Ltd., we specialize in delivering high-quality injection molding solutions tailored to our client's diverse needs. With years of experience and advanced manufacturing capabilities, we excel in producing precision-molded components for various industries. Partner with us for reliable and customized injection molding solutions.

More Prototype Injection Molding Companies

What is Prototype Injection Molding?

However, they are used to show clients and consumers an example of the product to work out more design details or gain permission before investing time and money into a long-run batch of injection molded parts.

The primary goal of prototype injection molding is to ensure that the mold is precisely developed and built before going into mass production. Prototypes are the most cost-effective alternative for small-scale or specialized enterprises.

A prototype mold is intended for the mass manufacture of 'correct material' prototypes and small to medium batches of plastic parts in the thousands. This process was created specifically for producing samples, prototypes, and small series at a low cost and in a short time.

Prototype Injection Molding Process

An injection molding machine, raw plastic material, and mold are all required for the injection molding process. In the injection molding machine, the plastic is melted and then injected into the mold, where it cools and solidifies into the final product. Then, plastic granules are placed in a hopper to begin the process.

The granules are then transferred from the hopper to a barrel and heated until molten. Once the granules have melted, a reciprocating screw forces them through the barrel until there is enough material to fill the mold. A shot is the amount of this material used at one time. The shot of liquid material is driven from the barrel into a channel of the mold called a sprue, then through a network of smaller channels called runners, and into the mold cavity after passing through a check valve.

The material begins to cool and harden once it reaches the mold by employing cooling lines surrounding the mold loaded with circulating water. As a result, the product will be solidified sooner.

The operator opens the mold once the material has fully cooled and set, and the molded object can then be automatically ejected. Finally, the runners are cut when the solid product is out of the mold and the product is complete.

Materials Utilized for Prototype Injection Molding

As previously stated, the prototype injection molding process is similar to the injection molding process in that it is used to make parts by injecting molten plastic into a mold. The plastic then hardens and undergoes secondary processes until it is in its final product form. A variety of materials can be used in this procedure, but thermoplastics are the most popular because of their diversity and useful qualities.

The thermoplastic material is forced into the mold after being heated and blended in a heated barrel; after the mold is filled, the material is cooled and hardens in the shape of the mold. The mold is created to meet the applications' standards and requirements. This is where the prototype is helpful because any flaws in the mold will be seen on the prototype.

Considerations for Prototype Injection Molding

It is critical to comprehend all the requirements and specifications, regardless of the application. Investing the effort to examine the intended applications thoroughly will significantly save development time and costs, and customers will be more likely to acquire a product tailored to their specific requirements.

This is why it is recommended to seek a reputable prototype injection molding firm to help design your molded product. They can assist in identifying design issues and revising specs to better suit the product's needs and budget.

Advantages and Disadvantages of Prototype Molding

Limited risk: Most injection prototype molds are composed of a soft metal alloy or aluminum, which decreases the manufacturing hazards significantly. In comparison to metals, these raw materials are significantly easier to machine. This aspect makes it easy to make changes and alterations to the cavities if necessary. Prototype molds provide a lot of flexibility, which is a significant plus.

Prohibitively expensive prototyping technology: Although the cost of producing a prototype mold is lower than that of producing a series mold, the initial investment is usually more when compared to other available technologies. The cost of skilled and technical labor and equipment is higher, and injection materials are likewise more expensive.

Choosing the Correct Prototype Injection Molding Company

To make sure you have the most productive outcome when purchasing Prototype Injection Molding from a Prototype Injection Molding Company, it is important to compare at least 4 Companies using our Prototype Injection Molding directory. Each Prototype Injection Molding Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Prototype Injection Molding business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Prototype Injection Molding companies with the same quote.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services