Plastic overmolding is a manufacturing process that involves molding a layer of plastic over a substrate material to create a finished product. This technique is used in a variety of industries to produce products that are durable, functional, and visually appealing. Read More…

For 50 years, LTM Plastics has been a leading manufacturer of injection molded plastics. When working with LTM Plastics, our customers can be assured that they are getting high quality products at a competitive price. We pride ourselves on our team’s communication and collaboration with our customers to meet their needs.

Hi-Rel Plastics & Molding, Inc. offers injection molding for a variety of industries. We can process an almost infinite variety of thermoplastic resins, our prices are competitive, our delivery is on time, and we provide superior customer service. Value-added services include label application, assembly services, and custom packaging and shipping. Our team has the knowledge and expertise to...

Quality Plastics, LLC. has become a premier leader in the injection molded plastics industry through our hard work and dedication. Out injection molding capabilities allow us to manufacture sizes from 55-1300 tons. Quality Plastics, LLC. is your trusted manufacturer for all injection molded plastics needs.

At TMF Plastic Solutions, precision and quality define our approach to injection molding. Advanced manufacturing capabilities and a deep understanding of material properties allow us to produce durable, high-performance plastic components for a variety of industries.

At Central Plastics, we’ve built our reputation on being the dependable partner that customers can count on—experienced, approachable, and always responsive. As a custom molder rooted in the heart of California, we specialize in high-quality injection molded plastics and thermoformed packaging.

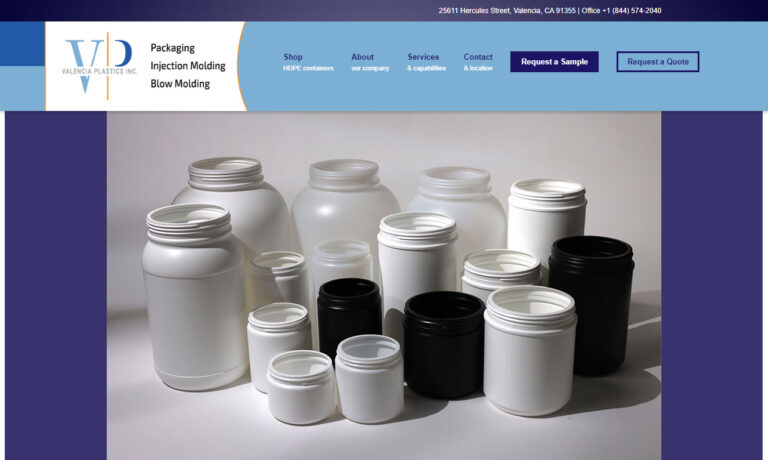

Valencia Plastics is your leading full-service injection molded plastics manufacturer. Our products are made with various materials, including urethane, polyurethane, nylon, acrylic, and polycarbonate. We offer a wide range of sizes from miniature items up to 7 lbs. large parts. We are ISO 9001:2015 compliant. Industries we serve include electrical, military, automotive, aerospace, and...

Abtec, Inc. is a manufacturer of injection molded thermoplastics for high-tech OEMs. Since 1981, we have provided quality injection molded plastics and engineering services to such industries as automotive, aerospace, dental, electronics, food handling, nuclear, reprographics and more. Our 21,000 square feet building operates 24-hours a day, 5 days a week. Contact us today!

At EXI-plast Custom Moulding Ltd., we specialize in delivering high-quality injection molding solutions tailored to our client's diverse needs. With years of experience and advanced manufacturing capabilities, we excel in producing precision-molded components for various industries. Partner with us for reliable and customized injection molding solutions.

At Zauderer Associates, Inc., we specialize in providing high-quality injection molding solutions tailored to meet the diverse requirements of our clients. Our team leverages extensive experience and advanced technology to produce precision-molded components that consistently exceed expectations.

You won’t find better quality injection molded plastics anywhere else in the industry. We have built ourselves up from a small manufacturing company to a large company with decades of experience.

At Nanoplas, Inc., we specialize in mold maintenance products for the plastic injection mold industry. With decades of experience and a commitment to innovation, we work closely with clients across industries to enhance the performance, reliability, and efficiency of injection molding operations.

More Plastic Overmolding Companies

Applications of Plastic Overmolding

One of the most common applications of plastic overmolding is in the automotive industry, where it is used to produce parts such as steering wheels, dashboard panels, and door handles. Plastic overmolding can also be found in consumer electronics, where it is used to create products such as cell phone cases, laptop shells, and remote controls. The medical device industry also relies on plastic overmolding to produce products such as hearing aids, insulin pumps, and surgical instruments. Other applications of plastic overmolding include sporting goods, such as golf club handles and bicycle grips, and industrial equipment, such as tool handles and control knobs.

Benefits of Plastic Overmolding

Plastic overmolding offers a number of benefits over other manufacturing techniques. First, it can improve the durability and longevity of a product by creating a strong bond between the substrate material and the overmolding material. This bond can protect the product from damage caused by impacts, vibration, and environmental factors such as moisture and temperature changes. Also, plastic overmolding can increase design flexibility by allowing manufacturers to combine different materials, colors, and textures in a single product. This can create a more visually appealing product that stands out from the competition. Additionally, plastic overmolding can reduce production costs by streamlining the manufacturing process. By combining multiple steps into a single process, manufacturers can save time and money on materials, labor, and equipment. Furthermore, plastic overmolding can enhance the aesthetic appeal of a product by creating a seamless and polished look. This can improve the product's perceived value and customer satisfaction. Finally, plastic overmolding can streamline the assembly process by reducing the number of parts and steps involved in creating a finished product. This can result in faster production times, lower labor costs, and fewer opportunities for errors or defects.

Plastic Overmolding Considerations

When using plastic overmolding, there are several important factors that manufacturers need to consider to ensure successful production. In addition to material selection, mold design, and process parameters, other factors include the size and shape of the substrate material, the type of adhesive or bonding agent used, and the post-molding finishing and assembly processes. The size and shape of the substrate material can impact the molding process and the final product's appearance and performance. The adhesive or bonding agent used must be compatible with the substrate and overmolding materials to create a strong and durable bond. Finally, post-molding finishing and assembly processes, such as trimming, polishing, and fastening, can impact the final product's aesthetic appeal and functionality. By carefully considering these factors, manufacturers can optimize the plastic overmolding process and produce high-quality products that meet customer needs and expectations.

Government Agencies Affecting Plastic Overmolding

In many countries, government agencies regulate the use of plastics in manufacturing to protect the environment and ensure public safety. For example, in the United States, the Environmental Protection Agency (EPA) regulates the disposal of plastic waste and sets standards for the use of certain chemicals in plastic production. Other regulatory bodies, such as the Occupational Safety and Health Administration (OSHA), establish guidelines for worker safety when handling plastic materials or working with plastic molding machinery. Manufacturers must comply with these regulations to avoid fines, legal action, or reputational damage. Additionally, some countries may require certifications or approvals for certain plastic overmolding processes or products before they can be sold in the market.

Industry Standards for Plastic Overmolding

In addition to these government agencies and their regulations, various industry organizations, such as the Society of Plastics Engineers (SPE) and the International Organization for Standardization (ISO), have developed their own standards for plastic overmolding to ensure consistency, quality, and safety in the manufacturing process. These standards cover various aspects of plastic overmolding, such as material selection, mold design, process parameters, testing, and quality control. For example, the ISO 13485 standard provides guidelines for the design, development, and manufacture of medical devices, including those that use plastic overmolding. Adherence to industry standards can help manufacturers demonstrate their commitment to quality and compliance, gain a competitive advantage, and meet customer expectations.

The Future of Plastic Overmolding

One emerging topic in plastic overmolding is the use of sustainable materials and processes. As consumers and governments become more concerned about the environmental impact of plastic waste, manufacturers are exploring new materials and technologies that reduce waste and improve sustainability. One approach is to use biodegradable or compostable materials, such as bio-based polymers or plant-based materials, in the overmolding process. Another approach is to use closed-loop recycling systems that enable manufacturers to recycle and reuse plastic waste generated during the overmolding process. Additionally, some manufacturers are exploring the use of renewable energy sources, such as solar or wind power, to reduce their carbon footprint. As sustainability becomes an increasingly important consideration for consumers and businesses, plastic overmolding manufacturers must adapt to these changing expectations and continue to innovate in this area.

Choosing the Right Plastic Overmolding Company

To ensure you have the most beneficial result when purchasing plastic overmolding from a plastic overmolding company, it is important to compare several companies using our directory of plastic overmolding companies. Each plastic overmolding company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the company for more information or to request a quote. Review each plastic overmolding business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple plastic overmolding companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services