It is the most common manufacturing technique employed in the making of objects we use each day, ranging from automotive dashboards to bottle caps and children’s toys. Plastic has become a popular alternative to metals, wood and glass as its wide range of properties are able to suit many different applications. Read More…

For 50 years, LTM Plastics has been a leading manufacturer of injection molded plastics. When working with LTM Plastics, our customers can be assured that they are getting high quality products at a competitive price. We pride ourselves on our team’s communication and collaboration with our customers to meet their needs.

Hi-Rel Plastics & Molding, Inc. offers injection molding for a variety of industries. We can process an almost infinite variety of thermoplastic resins, our prices are competitive, our delivery is on time, and we provide superior customer service. Value-added services include label application, assembly services, and custom packaging and shipping. Our team has the knowledge and expertise to...

Quality Plastics, LLC. has become a premier leader in the injection molded plastics industry through our hard work and dedication. Out injection molding capabilities allow us to manufacture sizes from 55-1300 tons. Quality Plastics, LLC. is your trusted manufacturer for all injection molded plastics needs.

At TMF Plastic Solutions, precision and quality define our approach to injection molding. Advanced manufacturing capabilities and a deep understanding of material properties allow us to produce durable, high-performance plastic components for a variety of industries.

At Central Plastics, we’ve built our reputation on being the dependable partner that customers can count on—experienced, approachable, and always responsive. As a custom molder rooted in the heart of California, we specialize in high-quality injection molded plastics and thermoformed packaging.

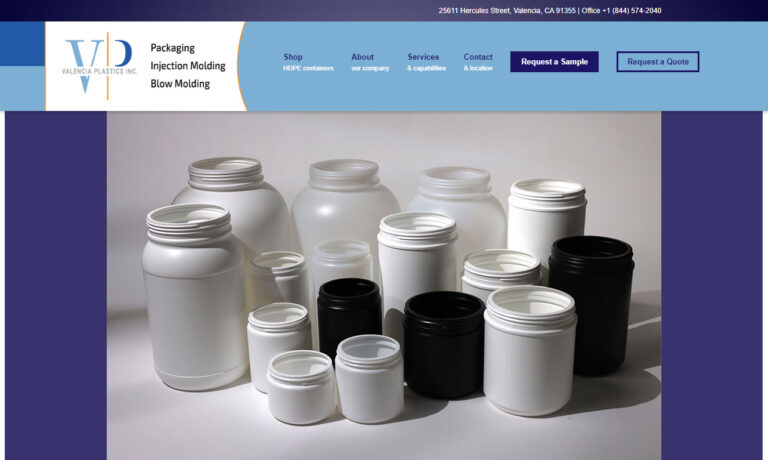

Valencia Plastics is your leading full-service injection molded plastics manufacturer. Our products are made with various materials, including urethane, polyurethane, nylon, acrylic, and polycarbonate. We offer a wide range of sizes from miniature items up to 7 lbs. large parts. We are ISO 9001:2015 compliant. Industries we serve include electrical, military, automotive, aerospace, and...

Abtec, Inc. is a manufacturer of injection molded thermoplastics for high-tech OEMs. Since 1981, we have provided quality injection molded plastics and engineering services to such industries as automotive, aerospace, dental, electronics, food handling, nuclear, reprographics and more. Our 21,000 square feet building operates 24-hours a day, 5 days a week. Contact us today!

At EXI-plast Custom Moulding Ltd., we specialize in delivering high-quality injection molding solutions tailored to our client's diverse needs. With years of experience and advanced manufacturing capabilities, we excel in producing precision-molded components for various industries. Partner with us for reliable and customized injection molding solutions.

At Zauderer Associates, Inc., we specialize in providing high-quality injection molding solutions tailored to meet the diverse requirements of our clients. Our team leverages extensive experience and advanced technology to produce precision-molded components that consistently exceed expectations.

You won’t find better quality injection molded plastics anywhere else in the industry. We have built ourselves up from a small manufacturing company to a large company with decades of experience.

At Nanoplas, Inc., we specialize in mold maintenance products for the plastic injection mold industry. With decades of experience and a commitment to innovation, we work closely with clients across industries to enhance the performance, reliability, and efficiency of injection molding operations.

More Plastic Molding Companies

Plastic polymers, in the form of thermoplastics, thermosets and elastomers, are a popular manufacturing material because of plastic's durability and malleability. The process of plastic molding is used for mass production and prototyping because of its ability to yield high runs at close tolerances.

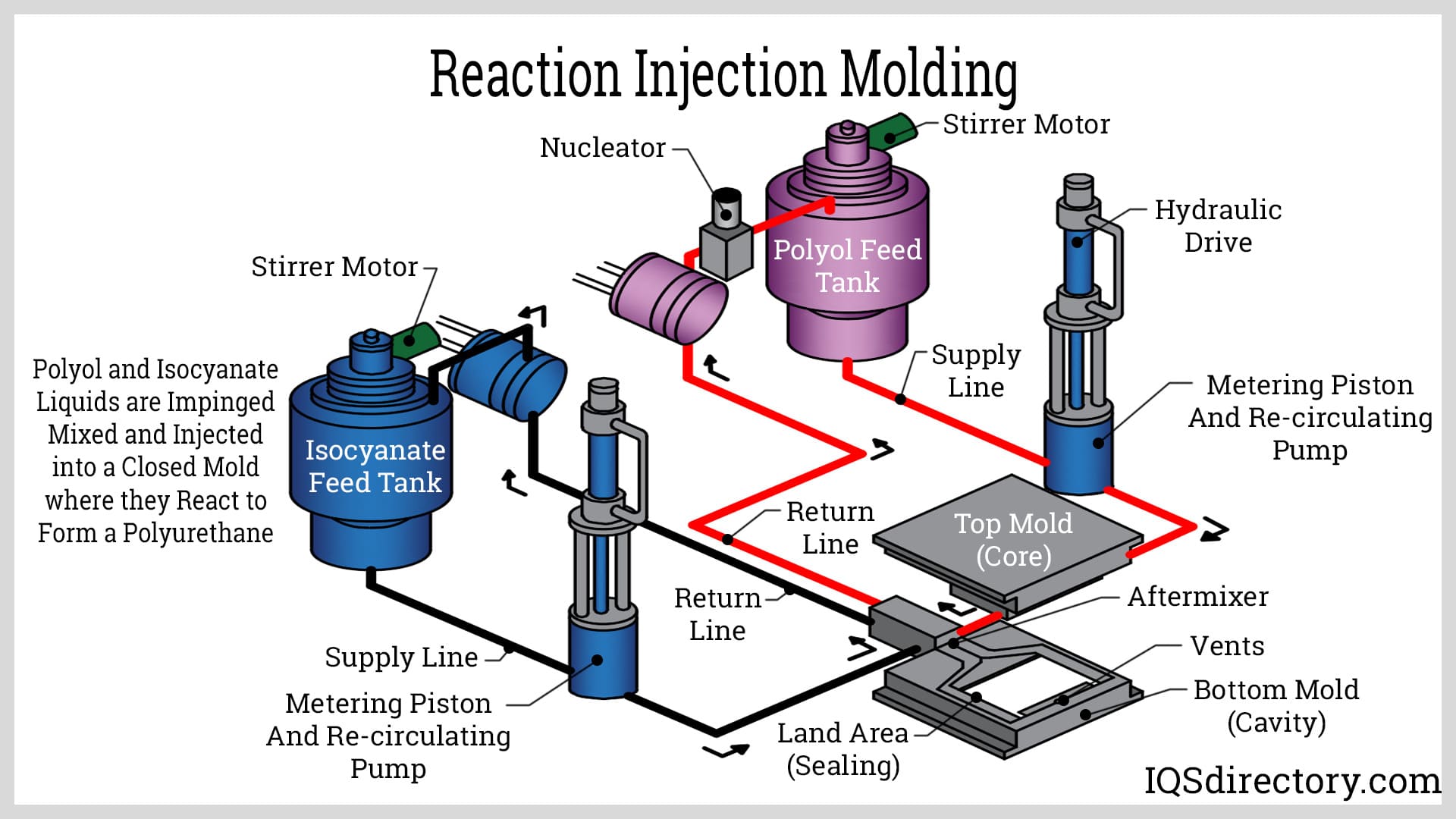

Plastic molding typically involves a pre-made mold and liquid plastics; however other manufacturing methods include vacuum forming, injection molding, blow molding and compression molding. The type of molding process chosen usually depends on the final intended use of the product being made, and the process is commonly used in the consumer, food service, medical, plumbing, computer and automotive industries.

Materials used in plastic molding differ in important ways: thermoplastics can be melted and molded into a wide variety of shapes as they become more pliable with the application of heat. Shapes can be remolded and adjusted if need be, however, thermoplastics tend to be more brittle in cold or freezing temperatures. Thermosets, such as melamine resin or polyimides, dry hard and brittle and can only be melted and molded once. They are however more suited to applications that require exposure to cold.

Elastomers, for example, those known as rubber, maintain a property of elasticity once cooled which is a required characteristic for some molded plastic products. Elastomers are used in the molding of children's toys, or other objects such as tool handles which benefit from the comfort of elasticity. There are numerous advantages to plastic molding, including: fast turnaround times, lower labor costs and the ability to make complex plastic products and minimal waste.

Other materials such as metal or wood are hard to mold, especially into small and complex shapes, and without having the ability to melt and harden, can result in heavy wastage costs. Plastic however, can be bent, twisted, squeezed or turned into an almost limitless range of shapes. The negligible amounts of waste produced can be recycled through the melt and mold process, making plastic molding a responsible manufacturing choice.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services