Plastic injection molding is a common and efficient method for creating plastic parts in the manufacturing sector. This injection molding process is used to produce a wide variety of products varying in size, complexity, and purpose. Read More…

For 50 years, LTM Plastics has been a leading manufacturer of injection molded plastics. When working with LTM Plastics, our customers can be assured that they are getting high quality products at a competitive price. We pride ourselves on our team’s communication and collaboration with our customers to meet their needs.

Hi-Rel Plastics & Molding, Inc. offers injection molding for a variety of industries. We can process an almost infinite variety of thermoplastic resins, our prices are competitive, our delivery is on time, and we provide superior customer service. Value-added services include label application, assembly services, and custom packaging and shipping. Our team has the knowledge and expertise to...

Quality Plastics, LLC. has become a premier leader in the injection molded plastics industry through our hard work and dedication. Out injection molding capabilities allow us to manufacture sizes from 55-1300 tons. Quality Plastics, LLC. is your trusted manufacturer for all injection molded plastics needs.

At TMF Plastic Solutions, precision and quality define our approach to injection molding. Advanced manufacturing capabilities and a deep understanding of material properties allow us to produce durable, high-performance plastic components for a variety of industries.

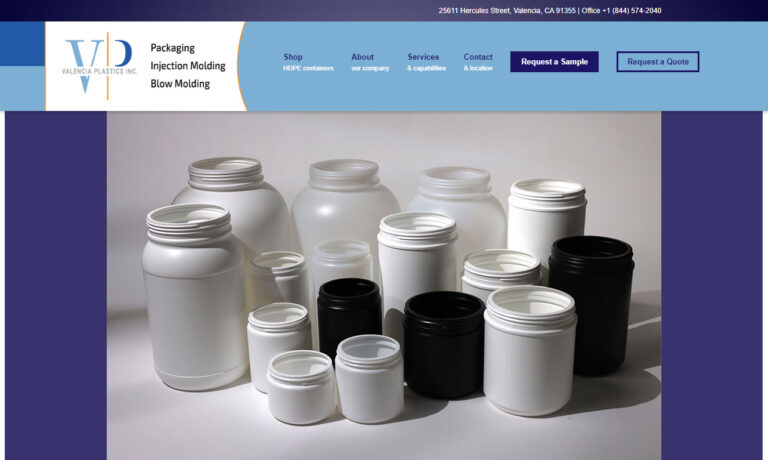

Valencia Plastics is your leading full-service injection molded plastics manufacturer. Our products are made with various materials, including urethane, polyurethane, nylon, acrylic, and polycarbonate. We offer a wide range of sizes from miniature items up to 7 lbs. large parts. We are ISO 9001:2015 compliant. Industries we serve include electrical, military, automotive, aerospace, and...

Abtec, Inc. is a manufacturer of injection molded thermoplastics for high-tech OEMs. Since 1981, we have provided quality injection molded plastics and engineering services to such industries as automotive, aerospace, dental, electronics, food handling, nuclear, reprographics and more. Our 21,000 square feet building operates 24-hours a day, 5 days a week. Contact us today!

At EXI-plast Custom Moulding Ltd., we specialize in delivering high-quality injection molding solutions tailored to our client's diverse needs. With years of experience and advanced manufacturing capabilities, we excel in producing precision-molded components for various industries. Partner with us for reliable and customized injection molding solutions.

You won’t find better quality injection molded plastics anywhere else in the industry. We have built ourselves up from a small manufacturing company to a large company with decades of experience.

At Zauderer Associates, Inc., we specialize in providing high-quality injection molding solutions tailored to meet the diverse requirements of our clients. Our team leverages extensive experience and advanced technology to produce precision-molded components that consistently exceed expectations.

More Plastic Injection Molding Companies

Raw plastic material, molds, a plastic injection mold, and other tools are used in this injection molding manufacturing process. These are necessary for the production of plastic injection molding. The injection molding machine first melts the raw plastic material. Then, molten plastic is pumped into the mold. Inside the mold, the plastic cools and solidifies, creating the finished product.

Thin-walled plastic parts are required for a variety of applications. They are utilized in numerous applications, with plastic housings being the most popular. Plastic housings are essentially a thin-walled shell with many bosses and ribs on the inside. They are the most typical element utilized in injection molding.

Numerous home furnishings, power tools, consumer gadgets, and even automotive dashboards use plastic housings. In addition, they are utilized in open containers such as buckets. Injection molding is also utilized to make commonplace goods like toothbrushes and tiny plastic toys. Additionally, injection molding is used to create medical products like syringes and valves.

Injection Molding Process Cycle

The cycle time for the injection molding technique is brief. Typically, this takes anywhere from two seconds to two minutes. This injection molding process comprises four phases as follows:

Injection Mold Clamping

Even before adding raw material to the mold, it is essential to make sure that the two sides of the mold are tightly closed within the clamping unit. During this procedure, one-half of the injection mold is fastened to the injection molding machine, and the other half is allowed to slide. The clamping mechanisms that hold the mold pieces together are hydraulically powered and exert a respectable amount of force.

As a result, the mold will be tightly shut after the molten material is poured inside. Additionally, based on the machine, the time required to close and clamp the mold must be determined; larger machines could take longer. This time can also be gauged using the injection molding machine's dry cycle time.

Plastic Injection

Pellets form the main supply of unprocessed plastic for this step. A shot, or the measurement of material that is poured into the mold, is poured into an injection molding device and pushed in the direction of the mold using the injection machinery. When heat and pressure are applied, the material melts.

As soon as the plastic melts, it is immediately pumped into the mold. High pressure is then applied to pack the material securely into the mold and maintain it there. Figuring out the injection time takes a lot of work due to complicated and erratic flow of molten plastic into the mold. However, injection time can be calculated using shot volume, injection power, and injection pressure.

Injection Cooling

The moment the molten plastic touches the surface of the interior of the mold, cooling sets in. It solidifies and assumes the proper shape as it cools, but it may contract as well. To lessen the shrinkage, more material is added at various points during the packing process. Finally, the mold is opened after the necessary cooling period has passed. This cooling time can be calculated by the maximum wall thickness of the product and the thermodynamic characteristics of the material.

Injection Mold Ejection

When the object is cooled, it must be ejected from the mold using an ejection mechanism lying in the back of the mold. When the package is opened, a tool can be used to force the object out. Further force should be applied to remove the component from the mold, which adheres to the mold because it shrinks as it cools. A mold-release chemical aids in the ejection of the cooled part. The substance is poured into the mold's surfaces before being injected into it.

The time required to eject and open the mold can be calculated using the dry cycle time. Each machine has a different dry cycle duration, as well as a different time required for the object to release from the mold. After extracting the last item from the machine, the mold is clamped shut and prepared for the next injection shot.

Product Post-Processing and Wrapup

Work, such as post-processing, is still needed once the injection molding cycle is over. Post-processing is necessary for almost all parts in order to remove any extra debris or flash that has collected on the element from bonding to the mold.

Advantages of Plastic Injection Molding

- Providing Uniformity: By using the same molds for all parts, it is easy to maintain the same dimensions (and therefore cost) for all of the pieces. Part tolerances typically range from +/-0.020 inches to +/-0.005 inches (+/-.500mm to +/-.125 mm), which is equivalent to CNC machined or 3D printed parts.

- Making Almost Identical Parts: Since every part originates from a small number of molds, even intricately detailed or complex pieces maintain consistency.

- Flexible Materials: Since injection molding can work with a huge variety of plastics and additives, it's simpler to locate plastic with the required characteristics.

- Recyclable Materials: Injection molding allows the reuse of discarded materials, cutting down on waste and the need to buy new materials.

- Low Labor Costs: Since machines do the majority of the work in injection molding, the only duties that require labor are supervision, quality assurance, and other comparable jobs.

Choosing the Right Injection Molding Company

To make sure you have the most beneficial outcome when purchasing Injection Molding from an Injection Molding Company, it is important to compare at least 5 or 6 Companies using our list of Injection Molding suppliers. Each Injection Molding Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Injection Molding business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Injection Molding companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services