Injection molders fabricate parts with a range of complexities, from simple shapes to close tolerance precision parts. From medical equipment, computer and automotive parts to office supplies, toys and tools, injection molded parts are found in almost every sector of industrial and consumer industries. Read More…

For 50 years, LTM Plastics has been a leading manufacturer of injection molded plastics. When working with LTM Plastics, our customers can be assured that they are getting high quality products at a competitive price. We pride ourselves on our team’s communication and collaboration with our customers to meet their needs.

Hi-Rel Plastics & Molding, Inc. offers injection molding for a variety of industries. We can process an almost infinite variety of thermoplastic resins, our prices are competitive, our delivery is on time, and we provide superior customer service. Value-added services include label application, assembly services, and custom packaging and shipping. Our team has the knowledge and expertise to...

Quality Plastics, LLC. has become a premier leader in the injection molded plastics industry through our hard work and dedication. Out injection molding capabilities allow us to manufacture sizes from 55-1300 tons. Quality Plastics, LLC. is your trusted manufacturer for all injection molded plastics needs.

At TMF Plastic Solutions, precision and quality define our approach to injection molding. Advanced manufacturing capabilities and a deep understanding of material properties allow us to produce durable, high-performance plastic components for a variety of industries.

At Central Plastics, we’ve built our reputation on being the dependable partner that customers can count on—experienced, approachable, and always responsive. As a custom molder rooted in the heart of California, we specialize in high-quality injection molded plastics and thermoformed packaging.

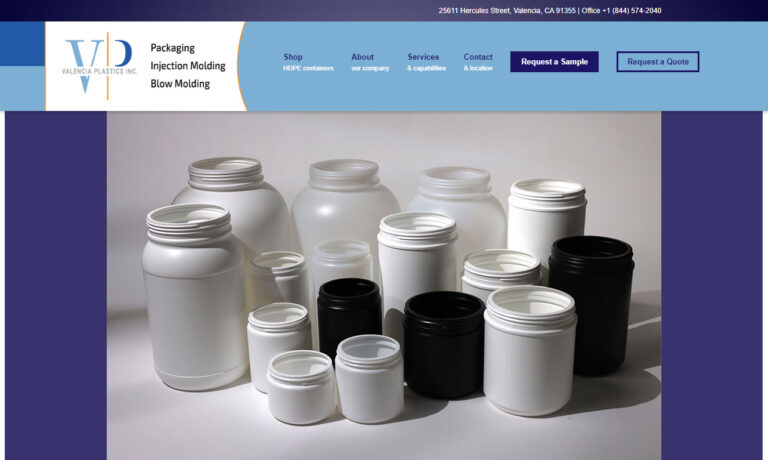

Valencia Plastics is your leading full-service injection molded plastics manufacturer. Our products are made with various materials, including urethane, polyurethane, nylon, acrylic, and polycarbonate. We offer a wide range of sizes from miniature items up to 7 lbs. large parts. We are ISO 9001:2015 compliant. Industries we serve include electrical, military, automotive, aerospace, and...

Abtec, Inc. is a manufacturer of injection molded thermoplastics for high-tech OEMs. Since 1981, we have provided quality injection molded plastics and engineering services to such industries as automotive, aerospace, dental, electronics, food handling, nuclear, reprographics and more. Our 21,000 square feet building operates 24-hours a day, 5 days a week. Contact us today!

At EXI-plast Custom Moulding Ltd., we specialize in delivering high-quality injection molding solutions tailored to our client's diverse needs. With years of experience and advanced manufacturing capabilities, we excel in producing precision-molded components for various industries. Partner with us for reliable and customized injection molding solutions.

At Zauderer Associates, Inc., we specialize in providing high-quality injection molding solutions tailored to meet the diverse requirements of our clients. Our team leverages extensive experience and advanced technology to produce precision-molded components that consistently exceed expectations.

You won’t find better quality injection molded plastics anywhere else in the industry. We have built ourselves up from a small manufacturing company to a large company with decades of experience.

At Nanoplas, Inc., we specialize in mold maintenance products for the plastic injection mold industry. With decades of experience and a commitment to innovation, we work closely with clients across industries to enhance the performance, reliability, and efficiency of injection molding operations.

More Injection Molding Companies

A few common examples of injection molding include catheters, contact lens containers, monitors, mop buckets, video game cartridges and screwdriver handles. Injection molding is primarily done with thermoplastics; however, a small amount of thermosets, biodegradable plastics and elastomers are also subjected to this process. There are many advantages to the injection molded process. Some of these advantages include high production rates and little need to finish parts after the molding is complete.

In addition, the cost per part is very low despite the high cost of tooling. Since injection molding can be used to produce very complex parts, injection molding is often used to produce parts that no other process can do. Other advantages of the injection molding process include the efficient use of materials and energy, precision-formed parts and a negligible amount of waste produced.

The most common type of injection molding machine are hydraulic oil machines, which use the force of hydraulic fluids to move the mold through the machine. Next in popularity is the toggle injection molding machine. Toggle machines use mechanical links to advance the mold in the machine. In addition, hybrid hydraulic/toggle machines are beginning to emerge in the injection molded plastics industry. Hybrid machines are used to eliminate some of the problems of other injection c molding machines, such as slow processing rates of parts and rapid wear and tear of machines.

No matter the machine, the injection molding process remains the same, beginning with heating the barrel section of the machine. Next, plastic pellets or granules are fed into a hopper where a screw pushes them to the heated barrel. In the barrel, the pellets or granules are heated to the melting point. The molten plastic material is then injected into the cavity of a split die chamber/mold, which is then clamped shut.

The plastic resin cools as water or other fluids circulate through the cooling system of the mold, extracting the heat. The injection molded part is held in the mold under high pressure until the part solidifies. The plastic part is finally ejected from the plastic injection mold, and the process begins again.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services