The injection molding process is a relatively simple concept. First, a material is heated and then injected into a mold; once it fills the mold, it is cooled, and the material hardens in the shape of the mold. Read More…

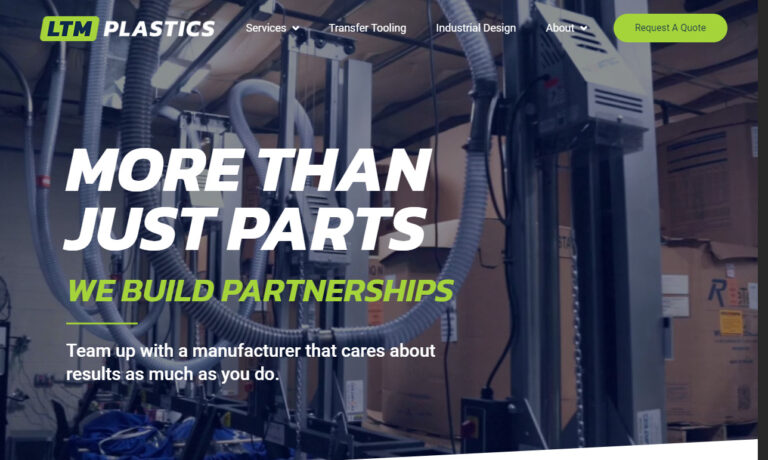

For 50 years, LTM Plastics has been a leading manufacturer of injection molded plastics. When working with LTM Plastics, our customers can be assured that they are getting high quality products at a competitive price. We pride ourselves on our team’s communication and collaboration with our customers to meet their needs.

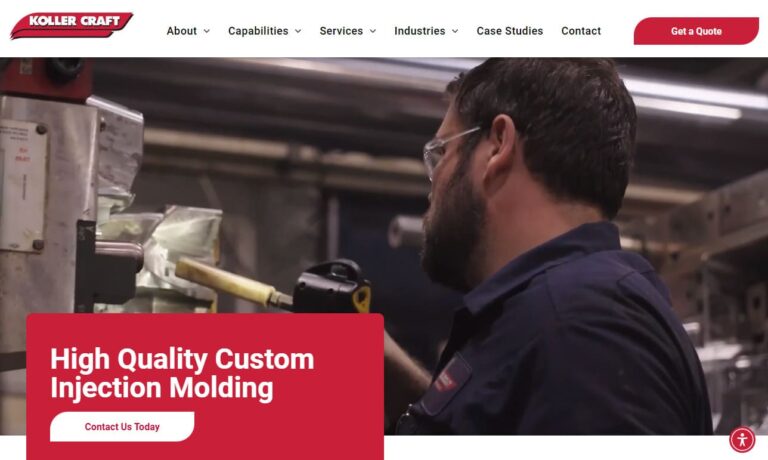

As one of the Midwest’s oldest plastic molders, Koller-Craft has craftsmanship built into its name. We take pride in our quality injection molding work. Large to small parts, short to long runs. Excelling at product design, prototyping, close tolerance molding, insert molding & secondary services.

Hi-Rel Plastics & Molding, Inc. offers injection molding for a variety of industries. We can process an almost infinite variety of thermoplastic resins, our prices are competitive, our delivery is on time, and we provide superior customer service. Value-added services include label application, assembly services, and custom packaging and shipping. Our team has the knowledge and expertise to...

We may have started small, but today, we offer our products and services to companies around the world. We are dedicated to our customers, and our goal is to offer better service and pricing to any customer no matter the size.

Our injection molding plastics services are designed to meet a wide range of applications. We work with various thermoplastics and provide custom molding solutions that ensure exceptional accuracy, strength, and durability. From small intricate parts to larger molded components, we tailor our approach to each project’s needs.

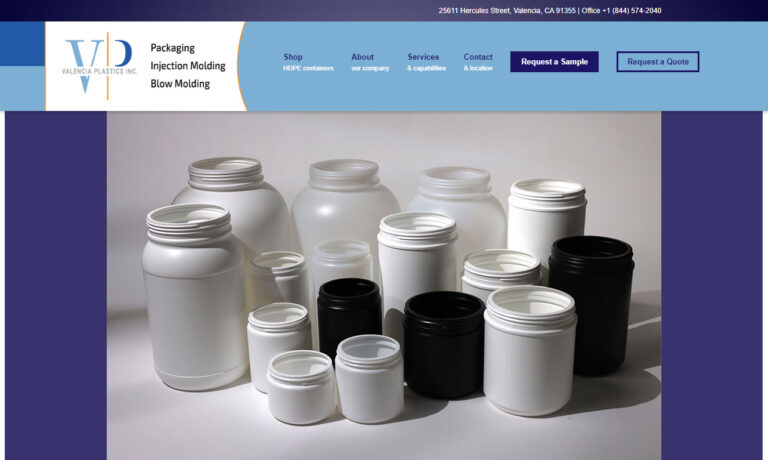

Valencia Plastics is your leading full-service injection molded plastics manufacturer. Our products are made with various materials, including urethane, polyurethane, nylon, acrylic, and polycarbonate. We offer a wide range of sizes from miniature items up to 7 lbs. large parts. We are ISO 9001:2015 compliant. Industries we serve include electrical, military, automotive, aerospace, and...

Abtec, Inc. is a manufacturer of injection molded thermoplastics for high-tech OEMs. Since 1981, we have provided quality injection molded plastics and engineering services to such industries as automotive, aerospace, dental, electronics, food handling, nuclear, reprographics and more. Our 21,000 square feet building operates 24-hours a day, 5 days a week. Contact us today!

You won’t find better quality injection molded plastics anywhere else in the industry. We have built ourselves up from a small manufacturing company to a large company with decades of experience.

At EXI-plast Custom Moulding Ltd., we specialize in delivering high-quality injection molding solutions tailored to our client's diverse needs. With years of experience and advanced manufacturing capabilities, we excel in producing precision-molded components for various industries. Partner with us for reliable and customized injection molding solutions.

More Injection Molded Part Companies

What are Injection Molded Parts?

The mold is designed based on the final product, which means that once the mold is removed, the material is in the final shape. Once the plastic shape has been removed from the mold, it must go through a few final finishing processes before it is complete. Injection molded parts are only as good as their molds; this is why prototyping is commonplace when dealing with injection molded parts.

Prototypes let customers see their final product before the manufacturer mass produces them, allowing them to redesign their mold if weaknesses or problems are seen in the prototype. As a result, prototype injection molding helps customers receive a high-quality product best fit for their applications.

As stated, injection molded parts can be found in virtually every industry. This is why it is important to understand the application and the requirements that go along with it.

The application and design specifications heavily influence the type of material used, the mold's design, and the overall process implemented to create the injection molded part.

This is why it is important to work with a trusted and experienced injection molded parts manufacturer who can provide technical knowledge and expert service. This ensures that you will receive a final product that fits your applications and meets your specifications.

Knowing your application is the first step to receiving an injection molded part that exceeds expectations.

Consideration When Making Injection Blow Molding Parts

Tooling Cost: Because tooling expertise and preform designs are highly guarded secrets by producers of injection blow-molded containers, the injection blow molding industry has been restricted in its growth. Tooling costs for goods like baby bottles, mascara, vaseline jars, pill bottles, deodorants, and other cosmetics can range from $12,000 for a single cavity to well over $140,000 for 16 cavities of the 50 mL distilled spirits PET container, which weighs 12.5 g and has a 9-second complete cycle.

Design of the part: The preform design is crucial in injection blow molding. The preform's body should have a wall thickness ranging from around 0.035 in (1 mm) to roughly 0.200 in (5 mm). The preform's length is designed to clear the bottle's inside length in the blow mold by around 0.005 in (0.125 mm). The preform stretches the least in the axial direction when the bottle is blown. In all practicality, the diameter of the core rod is defined by the maximum interior dimension (I-dimension) of the intended container's finish. It is vital to know what wall thickness is needed in the final blown article and the maximum inside diameter of the intended blown article when estimating the wall thickness of the preform in the main body. The hoop ratio is the ratio of the blown bottle's inside diameter (D1) to the inside diameter of the preform (D2).

If the blown article's wall thickness is 0.022 in (0.56 mm) and the hoop ratio is 3, the main body of the preform should have a wall thickness of about 0.066 in (1.67 mm). The preform's tip should be contoured to allow for efficient plastic flow but not bullet-shaped to allow for simple deflection owing to injection pressure. The tip of the preform design should be at least 0.0455 in (1.1 mm) flat. This number can be higher depending on the gate diameter orifice size. Because this material expands the most and travels the largest distance since it forms the heel area of the blow container, the outside radius of the core rod should be built with roughly 20% more material in this location. Injection blow mold tooling, like most injection molding, blow molding, and other plastic process tooling, is a separate topic. Injection blow molding is both an art and a science, and it is becoming more of a science with the introduction of new process controls.

Choosing the Correct Injection Molded Parts Supplier

To make sure you have the most constructive outcome when purchasing Injection Molded Parts from an Injection Molded Parts Supplier, it is important to compare at least 5 or 6 Companies using our list of Injection Molded Parts suppliers. Each Injection Molded Parts Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Injection Molded Parts company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Injection Molded Parts businesses with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services