EXI-plast Custom Moulding Ltd.

EXI-plast Custom Moulding Ltd.Request A Quote

Centralia, ON | 519-288-6421Since 1992, EXI-plast Custom Moulding is a full-service contract manufacturer of blow moulded products. Our array of industries served includes agriculture, consumer goods, waste collection, traffic control, automobile accessories, and much more. Located less than a few hours’ drive from Detroit and Toronto, our location allows for quick access to the Midwestern and Eastern US, as well as Ontario and Quebec. Our machines have a wide range in size, allowing us to take on a very wide variety of projects. Many projects in our portfolio include mating parts that are both made at EXI-plast, and our team can provide full or partial assembly of product with auxiliary parts. Shot sizes for our machines are as small as 6lbs and as large as 50lbs. With great range in platen sizes too, our ability to adapt to any project is unrivaled. EXI-plast also has various robotic trim cells to perform precise cuts in accordance with part drawings. Our engineering team assists in creating reliable and cost-efficient custom fixtures to achieve excellent part quality. In addition to elevating your projects to bring them to production, EXI-plast is well-versed in the use of postconsumer resins (PCR). By using PCR resin in our custom products, we play an important role in the circularity of plastics, keeping it out of landfills. No matter where a project is in its lifecycle, our team is prepared and equipped to take it on. This can range from an initial concept all the way to needing a new home for your existing mould for rapid production of any quantity. Contact us today and let our solutions bring success to your projects!

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

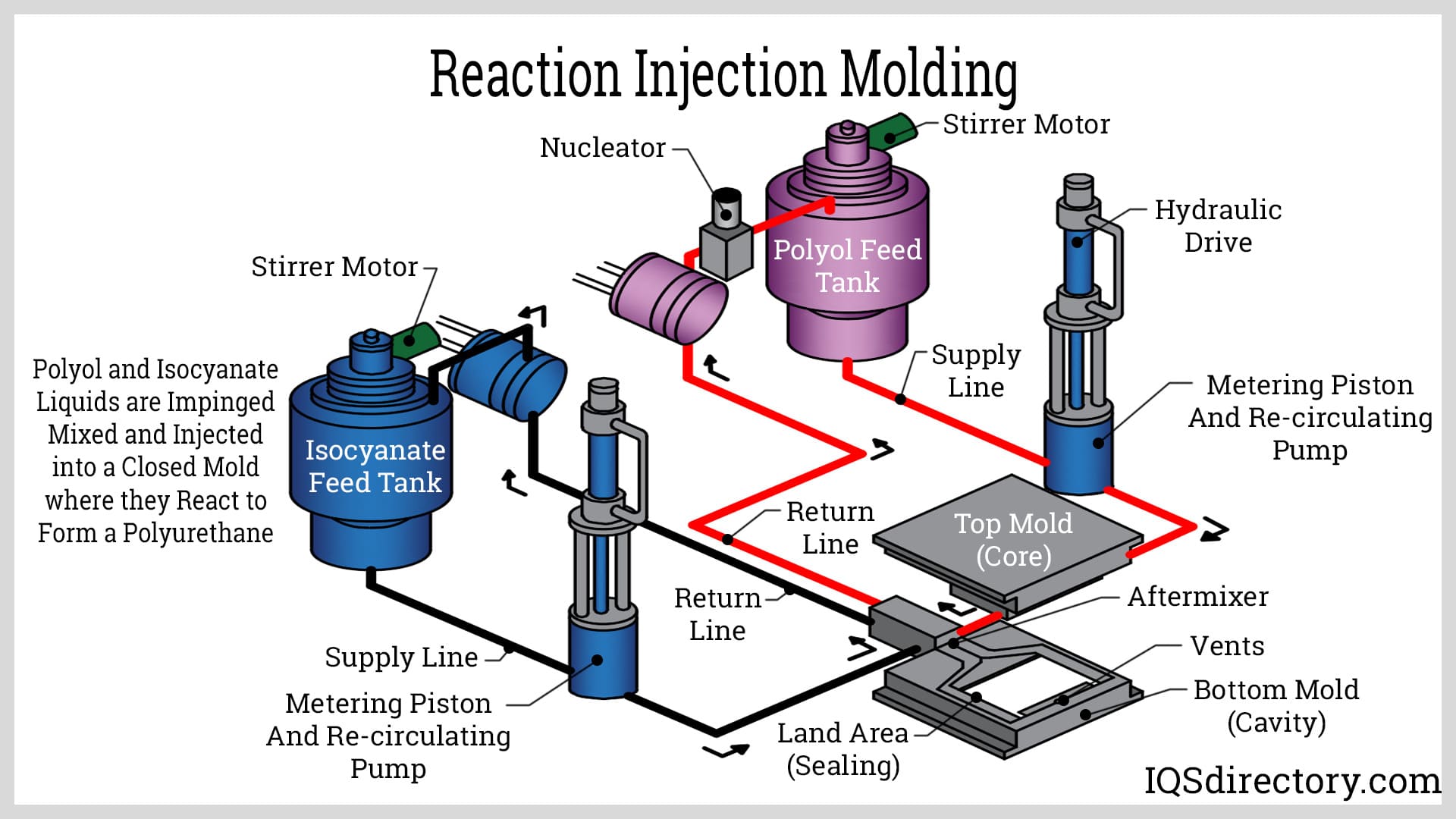

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services